Retro-9.5 Set Up

If you have any issues or questions, please contact us at

retrofix@swtexas.net or call us at 830-966-4664.

For RetroScan-HD software instructions, please click HERE.

NOTE: All instructions are for RetroScan-HD version 2.6.9

If you are using a previous version, please get your free update HERE.

NOTE: Please unpack carefully and keep the shipping box and internal packing materials for warranty shipping, if necessary. This is a precision optical device and the warranty does not cover repairs of return shipping damage if unit is not packaged appropriately using the original box and internal packing materials we have provided for safe transport.

Unit is designed to be stored and used in climate controlled

environment of 68-75 degrees F or 20-32 degrees C with minimum humidity.

Also, after unpacking, please let the unit set for about an hour at room temperature before attempting to use.

This is necessary as changes in humidity can alter the precision alignment on components within the unit.

Attempting to use the unit without letting it stabilize will not hurt anything but performance

may be affected until stabilization is complete.

After unpacking, please set unit on smooth, level surface.

If the unit rocks, adjust the leveling by loosening the screws on one of the plastic legs, pressing down on the unit from the top lightly, then gently tighten the screws. However, for proper operation, do not remove the plastic legs from the unit.

NOTE: Do not loosen or adjust any other screw on the Retro-9.5 unit.

All components are calibrated for optimal performance.

Making unauthorized adjustments to the gate or other components can affect performance and void your warranty.

The only exception is the user-adjustable tension clip (see bottom of this page).

Attach the provided USB cable to the back of the unit but DO NOT plug USB cable into the PC.

You will be notified during installation of the software when to connect the USB cable to the PC.

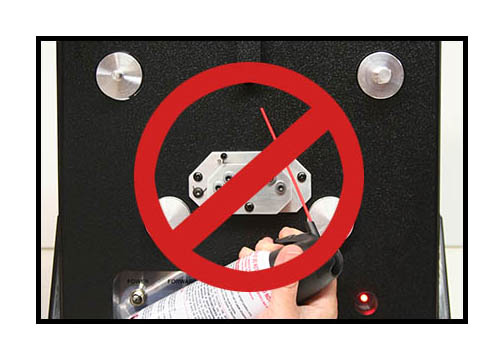

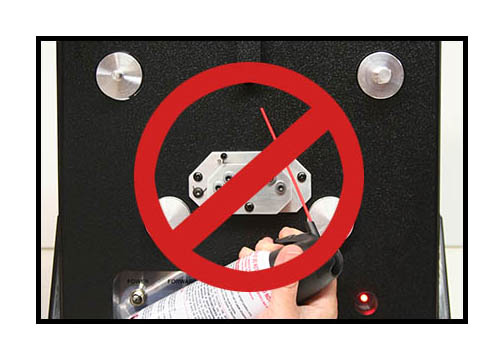

To dust off the unit, use a can of compressed air but do not invert the can nor turn it sideways.

Clear the nozzle first with a short blast and then bend then can's tube as shown to clear dust and debris from the mirror above and the gate below.

Do not touch the mirror and do not use any type of liquid cleaner on its surface. If necessary, use a cotton swab to gently wipe the surface and then follow up with a soft puff of compressed air to blow away cotton fibers.

Remove the accessories from the cardboard insert and locate all the parts shown above.

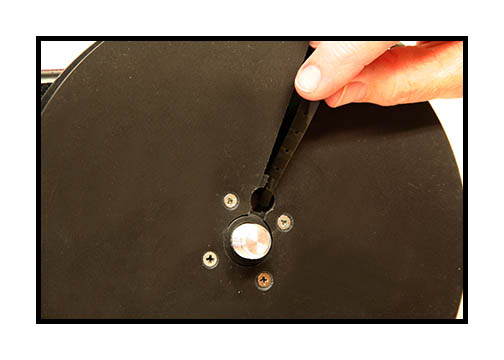

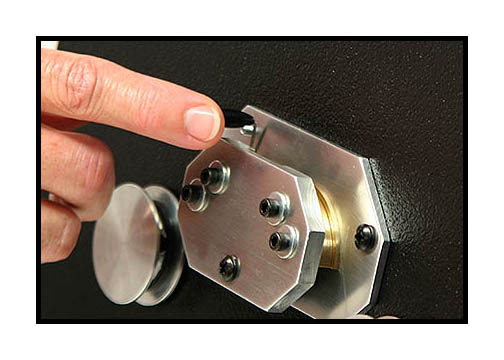

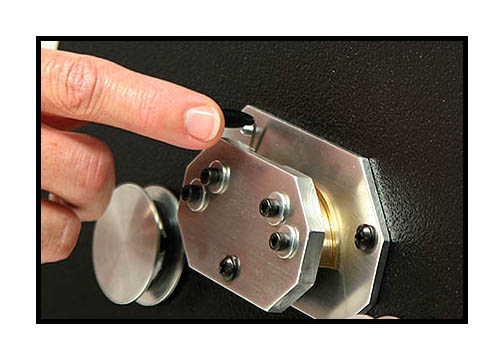

Insert the locking screw into the take up reel retainer and turn until the tip of the screw is almost flush with the surface as shown.

At this point, do not continue until software has been installed. Unit does not have to be turned on for installation.

Please make sure that all screen savers, sleep mode functions and antivirus are turned off during operation of this software.

Leaving these active can cause instability on some systems.

To download the latest RetroScan-HD software, please click HERE.

Make sure that your BIN registration key is on your desktop.

You will not be able to load the RetroScan-HD software without the BIN registration key.

For RetroScan-HD software instructions, please click HERE.

After launching the RetroScan-HD software, you will need to calibrate your unit before you can transfer.

To calibrate, you will need 9.5mm film. Put the reel to be transferred on the left spindle

and then loosely screw the reel retainer into place but do not tighten it.

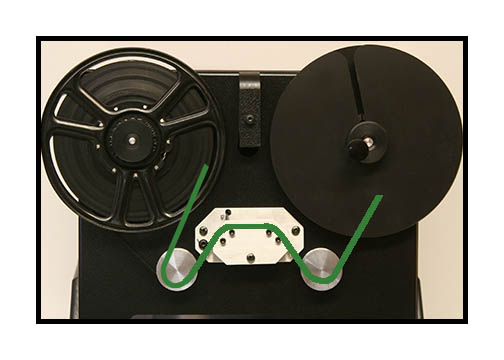

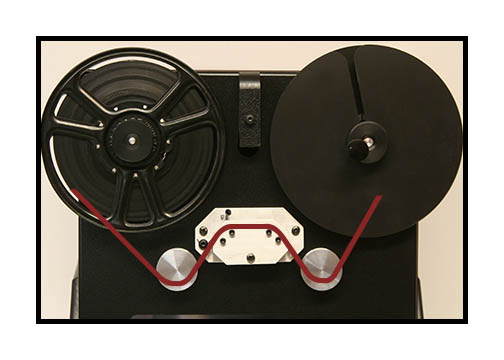

Put the take up reel on the hub and then insert the film as shown.

Screw on the reel retainer but do not tighten so that the reel turns freely.

Keep back tension on the supply reel and turn the take up reel a few turns to get a good wrap.

Gently move the film tension clip from the "closed" position to the "open" position as shown.

The purpose of the film tension clip is to keep the film pulled flat as it spans the open gate during transfer.

It is normal that this clip may lose tension over time. See bottom of this page about adjusting tension on this clip.

Then thread the film onto the gate as shown

It should be noted that, unlike 8mm or 16mm film, 9.5mm film often comes on supply reels facing

two different directions. These are known as an "A Wind" or a "B Wind". There is no right or wrong

orientation and there is really no way to predict what type of roll you will receive. However, as shown

in the photos, you can put the reel on either direction. You will know if it is correct if the images on

the screen face the correct direction. If they don't, then un-thread the film and reverse the reel.

It should be noted that the Retro-9.5 only rewinds in the "B Wind" orientation, even if your reel was

originally provided as an "A Wind".

Gently move the tension clip from the "open" position to the "closed" position as shown.

Your film is now threaded properly into the Retro-8 scanner.

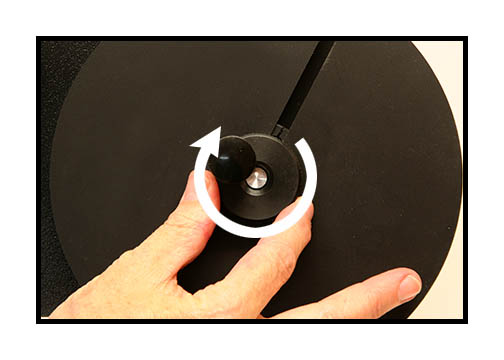

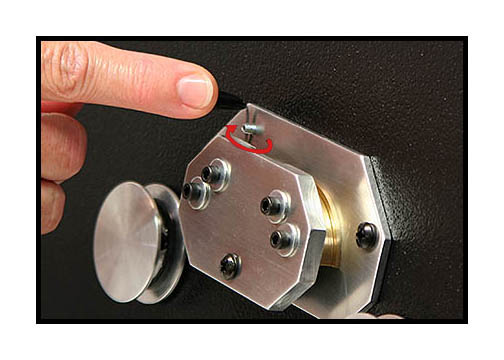

It should be noted that the take up reel is the only thing that pulls the film through the scanner. Normally, you can lock the reel to the hub by just holding the reel and tightening the black retainer against the reel firmly. But for runs longer than 50 feet, it is probably a good idea to also use the locking screw as shown. If using the locking screw, it is important to make sure the end of the screw aligns with the open space in the reel hub to prevent damage to the take up reel. Loosen the retainer and turn reel to new position, if necessary. Always loosen this retainer completely when rewinding.

After loading the 9.5 film, switch the unit to "forward".

Turn the exposure knob to the position shown then switch the unit to "run".

The unit will pull film for several seconds before the light comes on.

Once the light comes on, let the unit run for about 10-15 seconds.

After about 10-15 seconds, switch directly from "run" to "set up".

The unit will then stop with the lamp on.

WARNING: It should be noted that the LED is very, very bright.

Do not look directly into the gate with the LED on. Doing so runs the risk of damage to your eyes.

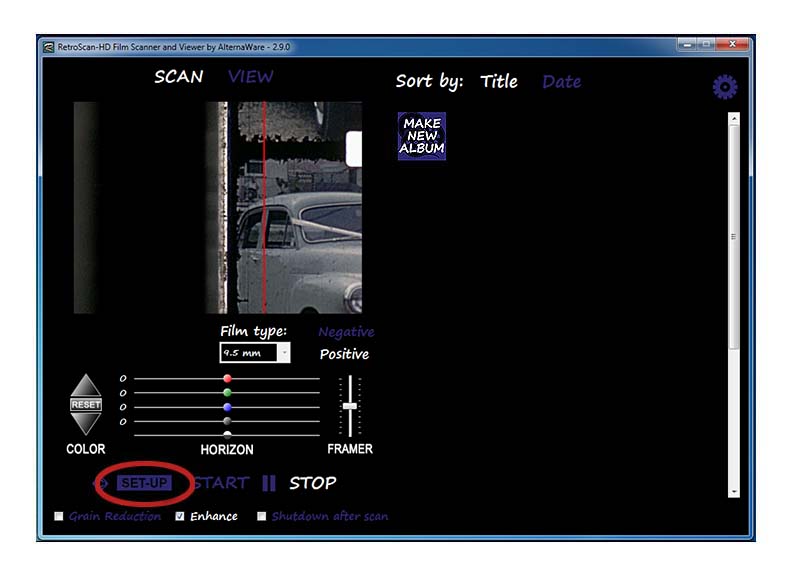

To calibrate your unit, select "9.5mm" in the film selection menu and then click the

"Calibration" symbol in the software.

You will see a thin, red line appear in the capture window as seen above.

Then click "Set Up" in the software one time. After a second or so, a live image of the gate will appear.

Most likely the sprocket hole of the film will not be properly aligned.

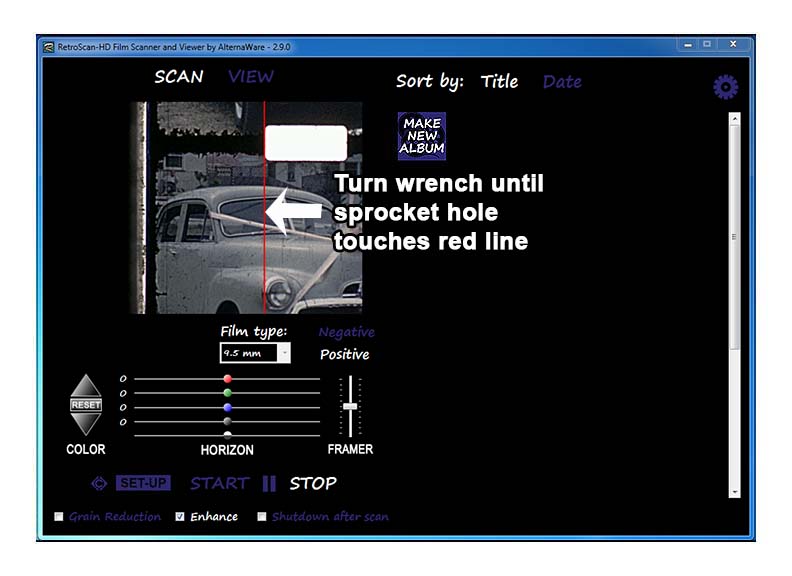

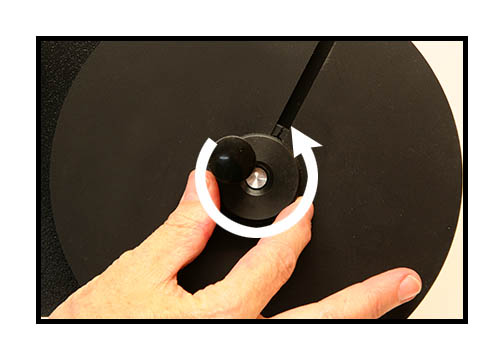

Start the unit running. While the film moves up the screen, use the hex

wrench and slowly turn the calibration screw clockwise.

As you slowly turn the hex wrench, the sprocket hole will move to the left. Do not turn too fast!

Watch the film as it moves up the screen and stop turning the hex wrench when the

edge of the sprocket hole aligns with the red line as shown above.

Continue to observe the film to make sure that it does not drift past the red line.

If you move the sprocket hole too far, or if it drifts past the line, simply turn the hex wrench the other direction.

When finished, click "Set Up" once to stop the calibration and then click

the "Calibration" symbol again to remove the red line.

(You may have to click the calibration symbol twice for it to respond.)

The Retro-9.5 unit has now been calibrated.

It is recommended to calibrate the unit at the beginning of each work day.

It should be noted that the RetroScan-HD software must be able to "see" the sprocket holes or the frames will not be captured. Extreme over or under exposure will blind the software to the sprocket holes. If this happens, just turn the knob back towards the center position and capture should resume.

To capture, again put the unit in the "run" mode and then click "start" on the RetroScan-HD software. When you finish your scan, click "stop" on the software and then stop the unit. If you let the entire reel transfer unattended, the Retro-9.5 unit and the RetroScan-HD software will stop automatically about 15 seconds after the reel ends or in the event of a film jam.

To rewind your film, loosen the locking screw until the tip is again flush on the back side and also loosen the take up retainer a few turns.

Tighten the source reel retainer firmly and move tension clip to the "open" position.

If the film was stopped before the tail end left the path, remove the film from the Retro-9.5and loop under guide rollers as shown. Do not rewind directly between reels or you risk the film rubbing against the overhead mirror assembly. This can damage both the film and the mirror assembly.

Put the Retro-8 unit in the "rewind" mode. It is advisable to hold your hand lightly on the reel on the right to provide back tension during rewind. It should also be noted that the unit will not rewind if it is in the "set up" mode. It must be in the "run" mode for the "forward" and "rewind" functions to work.

Congratulations! You have completed your first RetroScan-HD transfer!

Useful tips on your Retro-9.5 scanner

Though the unit itself has no wet-gate nor any kind of built-in film cleaner, we anticipate Retro-9.5 users being inventive enough to experiment with devices of their own design. To accommodate that, we have added some user accessory screws on the left side of the unit. These are wood screws and have no nut on the back side so they can be removed safely. These screws can be used to hold user-designed or aftermarket attachments in the future. Also, some older source reels may be warped. If you find they rub on the front of the unit, you can use the provided spacer to offset the reel.

Over time, the clip may lose its tension. Use a small hex wrench to loosen the screw out about 1/8th of an inch or about 4mm, pull the clip forward and down into the middle of the gate slightly as shown. Make sure that the bottom "hook" of the clip is firmly and completely against the screw shaft, then tighten the screw. To extend the life of the tension, always return the tension clip to the "closed" position when not transferring film.

NOTE: Do not loosen or adjust any other screw on the Retro-9.5 unit.

All components are calibrated for optimal performance.

Making unauthorized adjustments to the gate or other components can affect performance and void your warranty.

If you have any issues or questions, please contact us at

retrofix@swtexas.net or call us at 830-966-4664.

All information and imagery copyright MovieStuff, LLC

All right reserved.