Unpack the unit but do NOT plug it in.

You will need the

following:

Can of compressed

air.

SVHS cable of appropriate

length

Sharp, bright Super

8 film with good sprocket holes

(this should be disposable

film to practice with)

Scissors

If

you are international on 220VAC at 50 cycles,

you

do not need a transformer for this product.

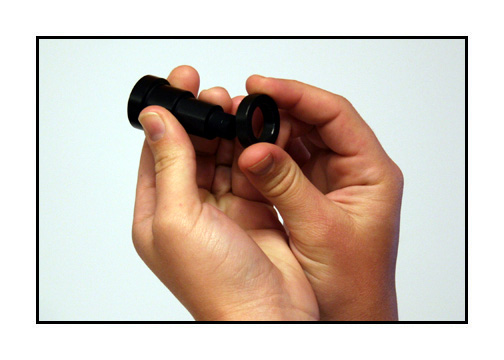

Step 1. For Super

8, insert the lens into the camera tube.

Step 2. For Regular

8, first install spacer ring.

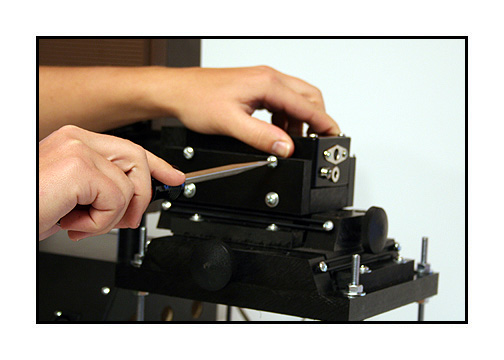

Step 3. Set camera

in cradle. Hold camera in position

and lightly tighten

side screws until firmly held

in place.

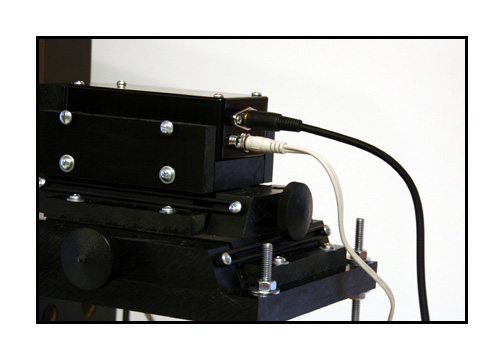

Step 4. Install camera

cables as shown.

(SVHS and power)

Step 5. Plug in unit.

Step 6. Turn power

on.

Verify that power

light is on.

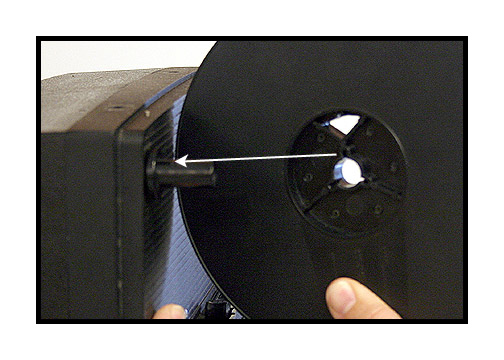

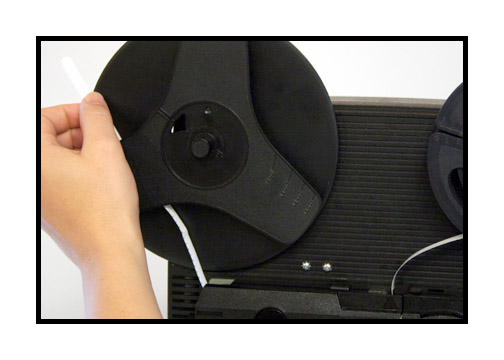

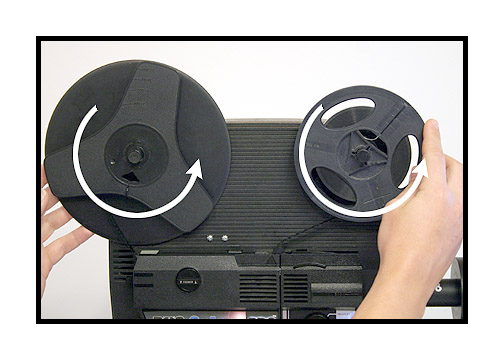

Step 7. Put provided

take up reel on back spindle. Make sure

that the slot of

the reel is on the small "fin"

found on the spindle

hub.

NOTE: This reel is

critical to the balance

and tension of the

system. Always use this take up

reel for proper performance.

Also, your source

reel should be lightweight and balanced.

Avoid heavy metal

reels with small hubs (the part the film

wraps around). Use

reels that are very much like the

take up reel for

best performance: Lightweight, balanced

and open so that

the reel does not bind the edges of the film.

Use of heavy, unbalanced

reels can interfere with

proper performance

and lead to flicker.

Also, make sure that

all film is cleaned and prepped.

All sprocket holes

should be in good shape and

the film should be

projectable for a stable image.

We recommend using

Edwals

AntiStat film cleaner.

Do not use FilmGuard

on these units.

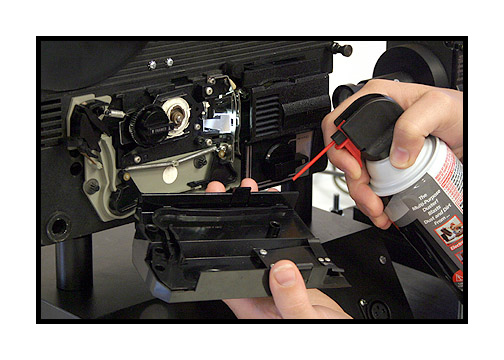

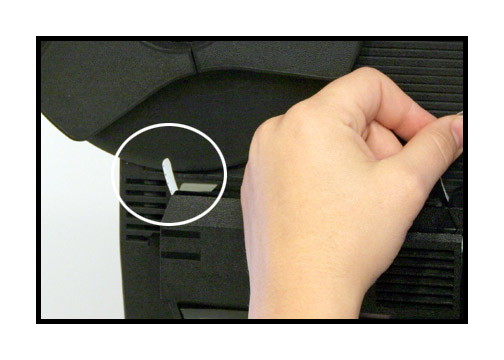

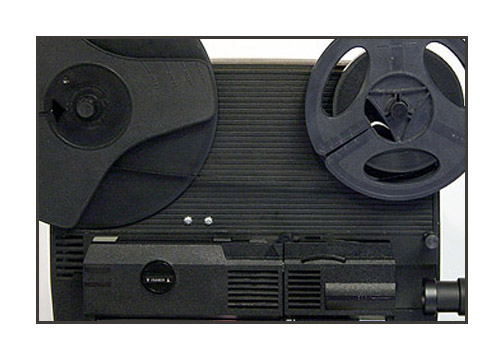

Step 8. Remove side

cover by squeezing the top

and bottom of the

panel and gently pulling loose.

Blow out film channel

on inside of cover.

Step 9. Blow out

film gate.

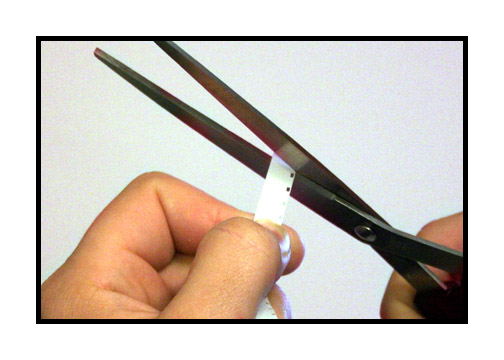

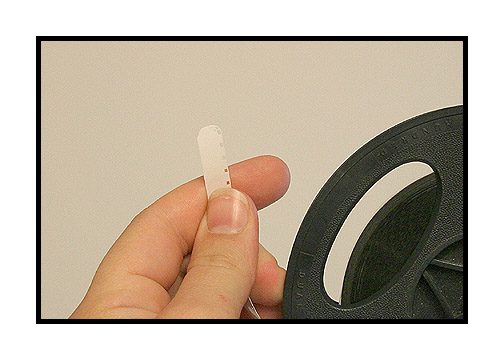

Step 10. Cut tip

of film leader in a curve.

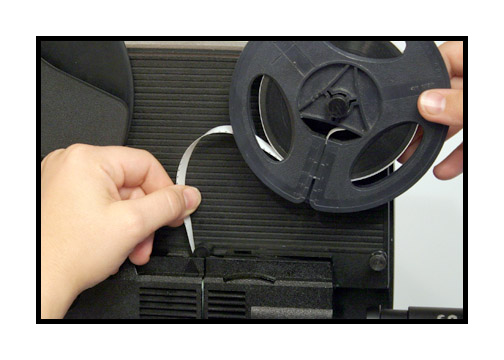

Step 11. Step to

right of unit and use

your left hand to

push film into the gate.

Only push about an

inch at a time.

If you feel resistance

after about an inch,

the film may be hitting

the advance claw. Turn the motor

on and off quick

one time to retract the claw.

Repeat if necessary

until the film will feed easily.

DO NOT TURN ON THE

PROJECTOR AS THIS UNIT HAS NO AUTOFEED.

Keep pushing the

film until it exits the back of the projector.

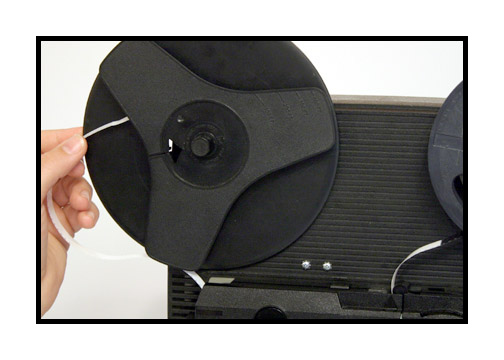

Step 12. Pull film

through projector.

Lay film on reel

and let sprocket holes catch barbs on hub.

(some reels may not

have the barbs, in which case use the slot)

Turn reel while keeping

film tension and take up slack.

NOTE: Never try to

load the film by taking the side cover off.

You can unload in

mid-roll but do not attempt to load in that fashion.

Step 13. Close gate

by turning knob to "project" or "lamp".

Step 14. Seat the

film in the gate by turning

the motor switch

on then off one time briefly.

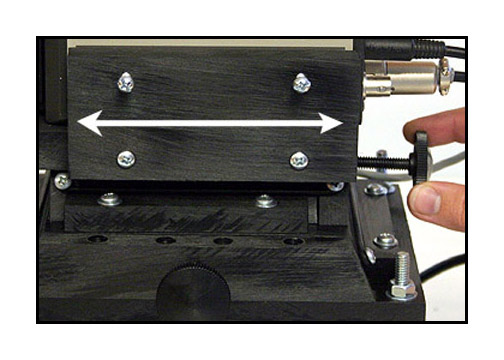

Step 15. Watch the

Velocity monitor and adjust the

camera side to side

using the knob as shown.

Step 16. Focus the

camera using the knob at the rear.

Step 17. Start your

transfer by turning on the motor.

The film should run

smoothly and flicker free.

During set up, if

you need to rewind the film a bit

to a previous section,

switch the motor off and open the

gate by turning the

control knob to off.

Manually move the

film forward or backward

but turning the reels

in the appropriate direction

at the same time,

to relieve tension.

If the film is caught

on the advance claw, just turn

the motor switch

on and off briefly to retract the claw.

After transfer, always

rewind between reels

outside the projector

mechanism to prevent film damage.

For efficiency, rewind

using seperate crank winders.

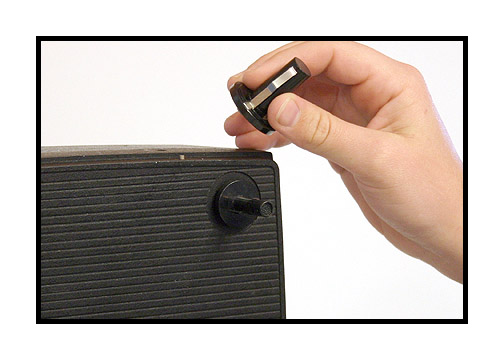

For regular 8mm film,

remove the super 8 adaptor.

Grab by the black

plastic only. Do not press down

on the silver metal

clip. Firmy but gently pull.

There is an 8mm spindle

underneath.

For manual exposure,

plug in the remote.

Adjust the knob until

you see the exposure you desire.

If the switch is

up, then the lamp is on all the way.

This can be handy

if you have dark, underexposed film

and don't want to

hold the remote all the time.

As noted on the website,

there is no auto exposure.

If you have any questions,

please feel free to call

Roger Evans at 830-966-4664.